Flat Packable Centering Dome / Cal Poly, San Luis Obispo, CA

Description

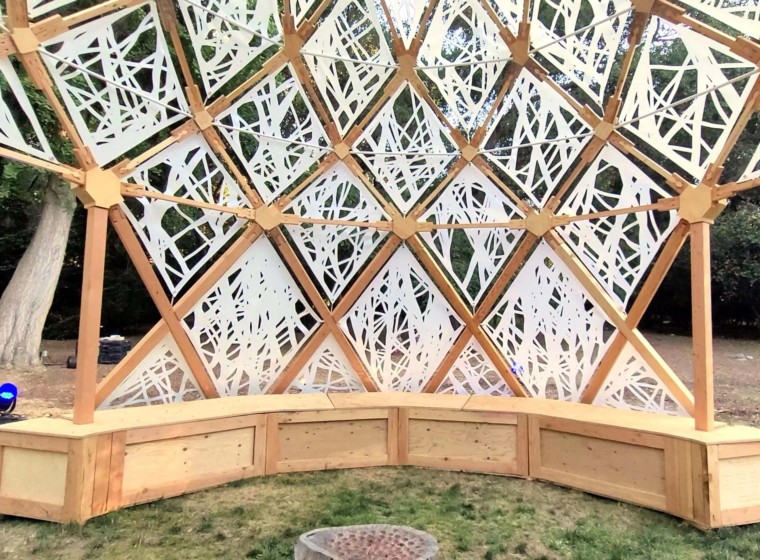

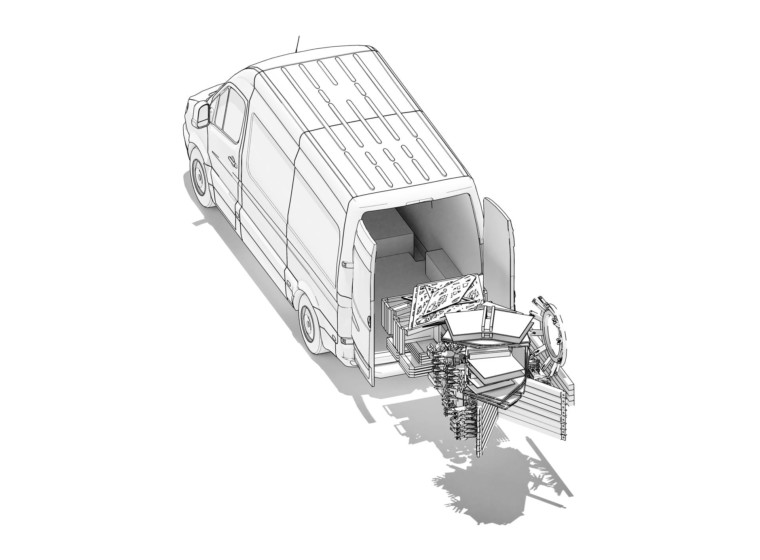

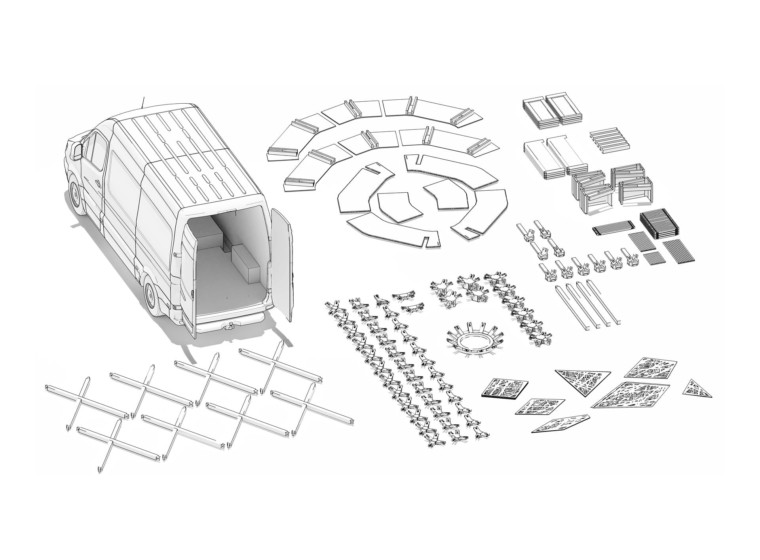

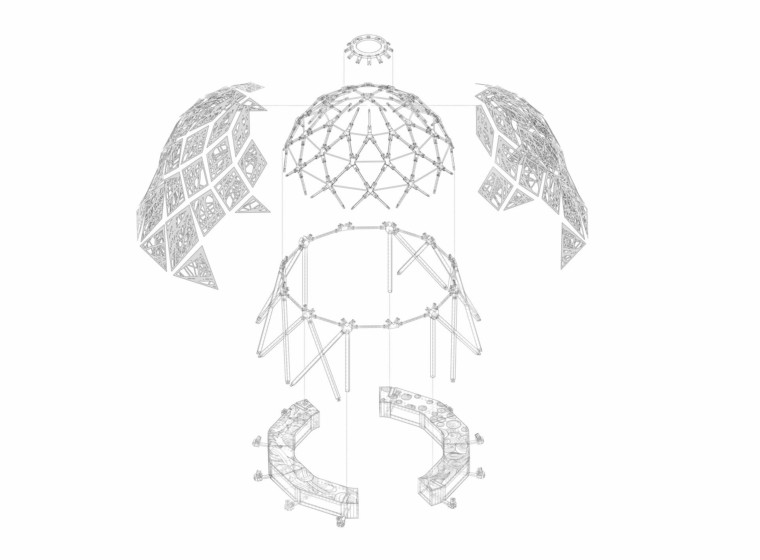

Cal Poly, San Luis Obispo, California Professors / Advisors Thomas Fowler IV, FAIA, Architecture, and Kevin Dong, SE, Phd, Architectural Engineering, collaborated with a multi-disciplinary team of 12 students (Architecture, Architectural / Mechanical Engineering, and Construction) as part of their Design Collaboratory, to fabricate a Flat Packable Centering Dome. Designing and building, using the foundational principles of circularity; reusing, repairing, and prototyping for remanufacturing, were the key concepts behind the design of the flat packable dome. The 16’ diameter / height of wooden structure was designed with the idea of ease of assembly / disassembly made with friction fit components and that can be transported via van and takes 4-persons 4-hours to assemble and half-this-time to disassemble. This project was developed as a proof-of-concept scaled down version from an earlier design for a Centering Center.

Vision

The vision is to develop an off-grid, sustainable retreat complex that combines spatial, audio and tactile qualities to create sensorial experiences that enhance self-awareness and healthy living while also embodying the best practices of conservation. The dome — when viewed from above — resembles a Dudley flower.

Three simultaneous paths

The instructor-advisors had the team develop three simultaneous paths of fabrication design: built a large-scale physical model, developed a series of Grasshopper definitions to simplify the number of dome pieces and worked in full scale to fabricate and test a dizzying number of options for finger joint connections. Going back and forth between the different scales and mediums of fabrication / testing were quite helpful in compressing the schedule to meet the short deadline of only 6 months to fabricate.

The materials for dome

Douglas Fir wood; 4x4s for posts, 2x4s ripped down to 2x2s, ¾” plywood laminated together using wood glue and CNC’d to develop the connection nodes and 5’ diameter compression ring, and continuous bench for structural support. A cable tension ring installed at the base of dome and laser cut Dudley flowered patterned vinyl skin connected to the frame. All component pieces of the dome were fabricated the same size and length; with only 4 types of multi-angled nodes and all connections were customized finger joint that work in friction fit mode with doweled connections only.

Author names

San Luis Obispo, California Professors:

Thomas Fowler IV, FAIA, Architecture

Kevin Dong, SE, Phd, Architectural Engineering

Photo Credits

-

01-centering-dome-site.jpg Adam John Albanese

01-centering-dome-site.jpg Adam John Albanese -

02-centering-dome-site.jpg Adam John Albanese

02-centering-dome-site.jpg Adam John Albanese -

03-centering-dome-site.jpg Adam John Albanese

03-centering-dome-site.jpg Adam John Albanese -

04-centering-dome-site.jpg Adam John Albanese

04-centering-dome-site.jpg Adam John Albanese -

05-centering-dome-site.jpg Adam John Albanese

05-centering-dome-site.jpg Adam John Albanese -

06-centering-dome-site.jpg Adam John Albanese

06-centering-dome-site.jpg Adam John Albanese